Course Description:

This course covers the electrical machines-three-phase

induction motor and generator, single phase ac motors, synchronous generator

and synchronous motor. It deals with the constructional details, operating

principle, characteristics, testing methods of the above machines.

Course content:

Unit 1. Three Phase Induction

Motor (15)

1.1 Constructional details – Yoke,

stator, stator windings, and rotor – squirrel cage type and phase wound type.

1.2 Operation – Production of

rotating magnetic field, operating principle, reversing the direction of

rotation.

1.3 Stand still condition –

equivalent circuit, starting current and starting torque.

1.4 Running condition - equivalent

circuit, running current and torque.

1.5 Torque-Speed characteristics,

effect of applied voltage on T-S characteristic, effect of rotor resistance on

T-S characteristic.

1.6 Power stages, losses and

efficiency

1.7 Starting methods – Direct

On-line starting, Primary resistor method, Autotransformer method, Star-Delta

method.

1.8 Speed control – Primary

voltage control method, Rotor resistance control method, frequency control

method, Cascade connection method.

1.9 Induction generator –

principle of operation, excitation requirement, voltage build-up process,

isolated and grid connected modes of operation.

Unit 2. Single Phase AC Motors

: (8 )

2.1 Split-phase induction

motor – Construction, concept of pulsating field produced by single phase

winding, double revolving field theory, Torque-speed characteristic,

self-starting by split-phase winding, Characteristics and

applications.

2.2 Capacitor start and

induction run motor – Operating principle, Characteristics and applications.

2.3 Capacitor start and run

motor- Operating principle, Characteristics and

applications

2.4 Shaded pole motor –

Operating principle, Characteristics and applications

2.5 AC series motor –

Operating principle, Characteristics and applications

Unit 3. Three-phase Synchronous

Generator (12)

3.1 Constructional details

and types.

3.2 Operation – Operating

principle, emf equation, armature winding parameters and its effect on emf

generation, relationship between speed, frequency and number of magnetic poles

in rotor, concept of geometrical degree and electrical degree.

3.3 Advantages of

stationary armature winding and rotating field winding.

3.4 Loaded operation –

effect of armature winding resistance, leakage reactance, armature reaction,

concept of synchronous impedance, equivalent circuit and phasor diagrams for

resistive, inductive and capacitive load, voltage regulation.

3.5 Synchronizing action

and synchronizing power Synchronous generator connected to infinite bus, effect

of excitation.

3.6 Parallel operation and

synchronization.

3.7 Related numerical

problems.

Unit 4. Synchronous Motor (10)

4.1 Principle of operation and

starting method.

4.2 General features and

applications

4.3 No-load and load operation

4.4 Effect of excitation on

armature current and power factor- V and inverted V curves.

4.5 Power-Angle characteristic.

Unit 1. Three Phase Induction Motor (15)

Introduction

• The

three-phase induction motors are the most widely used electric motors in

industry.

• They

run at essentially constant speed from no-load to full-load.

• However,

the speed is frequency dependent and consequently these motors are not easily

adapted to speed control.

• We

usually prefer d.c. motors when large speed variations are required.

• Like

any electric motor, a 3-phase induction motor has a stator and a rotor.

• The

stator carries a 3-phase winding (called stator winding) while the rotor

carries a short-circuited winding (called rotor winding).

• Only the stator winding is fed from 3-phase

supply.

• The

rotor winding derives its voltage and power from the externally energized

stator winding through electromagnetic induction and hence the name.

• The

induction motor may be considered to be a transformer with a rotating secondary

and it can, therefore, be described as a “transformer type” a.c. machine in

which electrical energy is converted into mechanical energy.

Advantages

(i) It has simple and rugged

construction.

(ii) It is relatively cheap.

(iii) It requires little

maintenance.

(iv) It has high efficiency and

reasonably good power factor.

(v) It has self starting torque.

Disadvantages

(i) It is essentially a constant

speed motor and its speed cannot be changed easily.

(ii) Its starting torque is

inferior to d.c. shunt motor.

Induction Machine

Construction

• A

3-phase induction motor has two main parts

(i) stator and (ii)

rotor.

• The

rotor is separated from the stator by a small air-gap which ranges from 0.4 mm

to 4 mm, depending on the power of the

motor.

1. Stator

• It

consists of a steel frame which encloses a hollow, cylindrical core made up of

thin laminations of silicon steel to reduce hysteresis and eddy current losses.

• A number of evenly spaced slots are provided

on the inner periphery of the laminations

• The

3-phase stator winding is wound for a definite number of poles as per

requirement of speed.

• Greater

the number of poles, lesser is the speed of the motor and vice-versa.

• When 3-phase supply is given to the stator winding,

a rotating magnetic field of constant

magnitude is produced.

• This

rotating field induces currents in the rotor by electromagnetic induction.

|

| Fig: Stator |

2. Rotor

The rotor, mounted on a shaft, is a hollow laminated core having slots on its

outer periphery. The winding placed in these slots (called rotor winding) may

be one of the following two types:

(i) Squirrel cage type (ii) Wound type

(i)

Squirrel cage rotor

• It

consists of a laminated cylindrical core having parallel slots on its outer

periphery.

• One

copper or aluminum bar is placed in each slot.

• All

these bars are joined at each end by metal rings called end rings [See Fig.

(8.2)].

• This

forms a permanently short-circuited winding which is indestructible.

• The

entire construction (bars and end rings) resembles a squirrel cage and hence

the name.

- The rotor is not connected electrically to the supply but has current induced in it by transformer action from the stator

Fig: Squirrel Cage Rotor

(ii) Wound rotor

• It consists of a laminated cylindrical core

and carries a 3- phase winding, similar to the one on the stator.

• The

rotor winding is uniformly distributed in the slots and is usually

star-connected.

• The

open ends of the rotor winding are brought out and joined to three insulated

slip rings mounted on the rotor shaft with one brush resting on each slip ring.

• The

three brushes are connected to a 3-phase star-connected rheostat.

• At

starting, the external resistances are included in the rotor circuit to give a

large starting torque.

• These resistances are gradually reduced to

zero as the motor runs up to speed.

1.2 Operation

Production of Rotating Magnetic Field Due

to 3-Phase Currents

When a

3-phase winding is energized from a 3-phase supply, a rotating magnetic field

is produced. This field is such that its poles do no remain in a fixed position

on the stator but go on shifting their positions around the stator. For this reason,

it is called a rotating field. It can be shown that magnitude of this rotating

field is constant and is equal to 1.5 fm where fm is the maximum flux due to

any phase.

Here Øm is the maximum flux due to any

phase. Fig. shows the phasor diagram of the three fluxes. We shall now prove

that this 3-phase supply produces a rotating field of constant magnitude equal

to 1.5 Øm.

The phasor

sum of - Øy and Øz is the resultant flux Ør [See Fig. (8.7)]. It is clear that:

Ør=√(

Øy²+

Øz²+2*

Øy*

Øz*cosΘ)=1.5Øm

(ii) At instant 2, the current is maximum (negative)

in Øy phase Y and 0.5 maximum (positive)

in phases X and Y. The magnitude of resultant flux is 1.5 Øm proved under:

At instant

2, wt = 30°. Therefore, the three fluxes are given by;

The phasor

sum of Øx, - Øy and Øz is the resultant flux Ør.

iii) At

instant 3, current in phase Z is zero and the currents in phases X and Y are

equal and opposite (currents in phases X and Y arc 0.866 ´ max. value). The

magnitude of resultant flux is 1.5 Øm as proved under:

At instant

3, wt = 60°. Therefore, the three fluxes are given by;

The phasor

sum of Øx, - Øy and Øz is the resultant flux Ør.

iv) At

instant 4, the current in phase X is maximum (positive) and the currents in

phases V and Z are equal and negative (currents in phases V and Z are 0.5 ´ max.

value). This establishes a resultant flux downward as shown under:

At instant

4, wt =

90°. Therefore, the

three fluxes are given by;

The phasor

sum of Øx, - Øy and - Øz is the resultant flux Ør.

It follows from the

above discussion that a 3-phase supply produces a rotating field of constant

value (= 1.5 Øm, where Øm is the maximum flux due to any

phase).

Speed of rotating magnetic field

The speed at which the rotating

magnetic field revolves is called the synchronous

speed (Ns).

where f is the frequency of the supply and P is the number of poles per phase.

Principle of Operation

Consider a portion of 3-phase

induction motor as shown in Fig. (8.13). The operation of the motor can be

explained as under:

(i) When

3-phase stator winding is energized from a 3-phase supply, a rotating magnetic

field is set up which rotates round the stator at synchronous speed Ns (= 120 f/P).

(ii) The

rotating field passes through the air gap and cuts the rotor conductors, which

as yet, are stationary. Due to the relative speed between the rotating flux and

the stationary rotor, e.m.f.s are induced in the rotor conductors. Since the

rotor circuit is short-circuited, currents start flowing in the rotor

conductors.

(iiii) The

current-carrying rotor conductors are placed in the magnetic field produced by

the stator. Consequently, mechanical force acts on the rotor conductors. The

sum of the mechanical forces on all the rotor conductors produces a torque

which tends to move the rotor in the same direction as the rotating field.

(iv) The

fact that rotor is urged to follow the stator field (i.e., rotor moves in the

direction of stator field) can be explained by Lenz’s law. According to this

law, the direction of rotor currents will be such that they tend to oppose the

cause producing them. Now, the cause producing the rotor currents is the

relative speed between the rotating field and the stationary rotor conductors.

Hence to reduce this relative speed, the rotor starts running in the same

direction as that of stator field and tries to catch it.

Click here to watch How Induction motor works?

Direction of rotating magnetic field

The phase sequence of the three-phase voltage applied to the

stator winding in Fig. (8.6 (ii)) is X-Y-Z. If this sequence is changed to

X-Z-Y, it is observed that direction of rotation of the field is reversed i.e.,

the field rotates counterclockwise rather than clockwise. However, the number

of poles and the speed at which the magnetic field rotates remain unchanged.

Thus it is necessary only to change the phase sequence in order to change the

direction of rotation of the magnetic field. For a three-phase supply, this can

be done by interchanging any two of the three lines. As we shall see, the rotor

in a 3-phase induction motor runs in the same direction as the rotating

magnetic field. Therefore, the direction of rotation of a 3-phase induction

motor can be reversed by interchanging any two of the three motor supply lines.

Slip

The difference between the

synchronous speed Ns

of

the rotating stator field and the actual rotor speed N is called slip. It is

usually expressed as a percentage of synchronous speed i.e.,

(i)

The

quantity Ns

- N

is sometimes called slip speed.

(ii)

When

the rotor is stationary (i.e., N = 0), slip, s = 1 or 100 %.

(iii)

In

an induction motor, the change in slip from no-load to full-load is hardly 0.1%

to 3% so that it is essentially a constant-speed motor.

Rotor Current

Frequency

The frequency of a voltage or current induced due to the relative speed between a vending and a magnetic field is given by the general formula;

Frequency = NP/120

P = Number of poles

For a rotor speed N, the relative speed between the rotating flux and the rotor is Ns - N. Consequently, the rotor current frequency f' is given by;

i.e., Rotor current frequency = Fractional slip x

Supply frequency

At

any slip s,

Rotor e.m.f./phase

= sE2

Rotor

reactance/phase = sX2

Rotor frequency =

sf

where E2,X2 and

f are the corresponding values at standstill

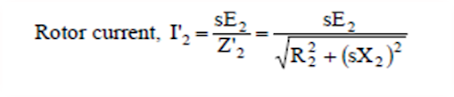

Rotor Current

At standstill. Fig. (8.15 (i)) shows one phase of the rotor circuit at standstill.

When running at slip s. Fig. (8.15 (ii)) shows one phase of the rotor circuit when the motor is running at slip s.

Rotor Torque

The torque T developed by the rotor

is directly proportional to:

(i) rotor current

(ii) rotor e.m.f.

(iii) power factor of the rotor circuit

\ T µE2I2 cosf2 or, T = KE2 I2 cosf2

where I2 = rotor current at standstill

E2 = rotor e.m.f. at standstill

cos f2 = rotor p.f. at standstill

Note.

The values of rotor e.m.f., rotor current and rotor power factor are taken for

the given conditions.

Analysis at Standstill Condition

Standstill

condition is the instant of starting. At this instant, the speed of the rotor

is zero. Therefore the relative speed Ns-N is maximum, slip is maximum(s=1) and

maximum emf will induce in the rotor circuit(just like in secondary winding in

a transformer) and the frequency of emf induced in rotor circuit is same as

that of supply voltage frequency ‘f’ and is given by :

f=

(Ns*P)/120

The

equivalent circuit of the induction motor at standstill condition is very

similar to the equivalent circuit of a transformer. The stator winding is

analogous to the primary winding of the transformer and rotor circuit is

analogous to the secondary winding of the transformer. The per phase equivalent

circuit of a three phase induction motor is as shown in fig8.11.

Let E2 =

rotor e.m.f. per phase at standstill

X2 = rotor

reactance per phase at standstill

R2 = rotor

resistance per phase

Analysis of Running Condition

The equivalent circuit of

the induction motor at running condition can be written as:

Let the

rotor at standstill have per phase induced e.m.f. E2, reactance X2 and resistance

R2. Then under running conditions at slip s,

Running Torque, Tr µ E'2 I'2 cosf'2

Torque-Slip Characteristics

If a curve

is drawn between the torque and slip for a particular value of rotor resistance

R2, the graph thus obtained is called torque-slip characteristic. The general

equation of torque is given by:

Thus for maximum

torque (Tm)

under running conditions :

Rotor resistance/phase =

Fractional slip ´ Standstill

rotor reactance/phase

Hence

maximum torque will develop at a speed corresponding to slip s=R2/X2. If the

motor is overloaded so that speed goes below this value, the motor will not be

able to develop more torque to overcome the increased load.

Effect of Change of Supply

Voltage

Therefore, the starting torque is very sensitive to changes

in the value of supply voltage. For example, a drop of 10% in supply voltage

will decrease the starting torque by about 20%. This could mean the motor

failing to start if it cannot produce a torque greater than the load torque

plus friction torque.

Effect of rotor

resistance on T-S characteristics

At normal

running condition, Tr µ s/R2

At starting, Ts µ R2/s

Therefore, if we add some resistance in series with rotor winding (that

we can do in case of slip-ring rotor), the starting torque will increase, but

running torque will decrease. Fig below show the effect of rotor resistance on

the T-S characteristics of induction motor.

Here two

curves are shown- one for rotor resistance of R2 and other for rotor

resistance of 2R2. At a particular speed N1, the running

torque is equal to OT1 when rotor resistance is R2. At

the same speed, the running torque is only OT2 when the rotor resistance is 2R2.

The starting torque of the motor is equal to OC with rotor resistance R2

and the motor gives higher starting torque with rotor resistance 2R2.

Hence, external rotor resistance are used where high starting torque is

required. Once the motor has picked up to its normal operating speed (N), the

external rotor resistance is removed to improve the running torque.

Example 9.11

A 4-pole, 3-phase, 50Hz induction

motor has a star connected rotor. The rotor has a resistance of 0.1 ohm per

phase and standstill reactance of 2 ohm per phase. The induced emf between the

slip rings is 100V. If the full load speed is 1460 rpm, calculate

i.

The slip

ii.

The emf induced in the rotor in each

phase

iii.

The rotor reactance per phase

iv.

The rotor current and

v.

Rotor power factor.

Assume slip rings are short

circuited.

Example: 9.1

A 6-pole, 3 phase induction motor is

connected to 50 Hz supply. If it is running at 970 rpm, find the slip. (ans=3%)

Example 9.2

A 3-phase induction motor is wound

for 4 poles and is supplied from 50 Hz system. Calculate: i) the synchronous

speed ii)the speed of the motor when slip is 4% and iii) the rotor current

frequency when the motor runs at 600 rpm.(ans: 1500rpm, 1440rpm, 30Hz)

Example 9.3

A 50 Hz 4-pole 3-phase induction

motor has a rotor current of frequency of 2 Hz. Determine i)the slip and ii)

speed of the motor. (4%, 1440rpm)

Example 9.4

A 500 hp, 3-phase, 440 V, 50 Hz induction

motor has a speed of 950 rpm on full load. The machine has 6-poles. Calculate

the full load slip and rotor frequency. (5%, 2.5 Hz)

Tutorials

1.

A 2-pole, 3-phase,50-Hz induction

motor is running on no load with a slip of 4%. Calculate i) synchronous speed

ii) speed of the motor (ans: 3000rpm, 2880rpm)

2. The frequency of emf in the stator of a 4-pole,3-phase induction motor is 50Hz and that in the rotor is 1.5 Hz. Determine i) the slip ii) speed of the motor (ans: 3%, 1455 rpm)

3. A 3-phase, 50Hz induction motor has 8 poles. If the full-load slip is 2.5 %, determine i) synchronous speed ii) rotor speed iii) rotor frequency (ans: 750rpm, 731 rpm, 1.25Hz)

1.6 Power

stages, losses and efficiency

The input

electric power fed to the stator of the motor is converted into mechanical

power at the shaft of the motor. The various losses during the energy

conversion are:

1. Fixed

losses

(i) Stator

iron loss

(ii)

Friction and windage loss

The rotor

iron loss is negligible because the frequency of rotor currents under normal

running condition is small.

2.

Variable losses

(i) Stator

copper loss

(ii) Rotor

copper loss

Fig. (8.20) shows how electric power fed to the stator of an induction motor suffers losses and finally converted into mechanical power.

The

following points may be noted from the above diagram:

(i)

Stator input, Pi = Stator output + Stator losses

=

Stator output + Stator Iron loss + Stator Cu loss

(ii)

Rotor input, Pr = Stator output

It is because stator output is entirely transferred to the rotor through air gap by electromagnetic induction.

(iii)

Mechanical

power available, Pm = Pr - Rotor Cu loss

This mechanical power available is the gross rotor output and will produce a gross torque Tg.

(iv)

Mechanical

power at shaft, Pout = Pm - Friction and

windage loss

Mechanical power available at the

shaft produces a shaft torque Tsh.

Clearly, Pm - Pout = Friction and

windage loss

Induction Motor

Torque

Rotor Output

If Tg

newton-metre is the gross torque developed and N r.p.m. is the speed of the rotor,

then,

Gross rotor

output = 2pNTg/60 watts

If there

were no copper losses in the rotor, the output would equal rotor input and the

rotor would run at synchronous speed Ns.

Starting of 3-Phase Induction Motors

The induction motor is

fundamentally a transformer in which the stator is the primary and the rotor is

short-circuited secondary. At starting, the voltage induced in the induction

motor rotor is maximum (Q s

= 1). Since the rotor impedance is low, the rotor current is excessively large.

This large rotor current is reflected in the stator because of transformer

action. This results in high starting current (4 to 10 times the full-load current)

in the stator at low power factor and consequently the value of starting torque

is low.

Methods of Starting 3-Phase Induction

Motors

The method to be employed in

starting a given induction motor depends upon the size of the motor and the

type of the motor. The common methods used to start induction motors are:

(i)

Direct-on-line starting

(ii)

Stator resistance starting

(iii)

Autotransformer

starting

(iv)

Star-delta starting

(v)

Rotor resistance

starting

Methods (i) to (iv) are

applicable to both squirrel-cage and slip ring motors. However, method (v) is

applicable only to slip ring motors. In practice, any one of the first four

methods is used for starting squirrel cage motors, depending upon ,the size of

the motor. But slip ring motors are invariably started by rotor resistance

starting.

(i) Direct-on-line starting

This method of starting in just what the name implies—the

motor is started by connecting it directly to 3-phase supply. The impedance of

the motor at standstill is relatively low and when it is directly connected to

the supply system, the starting current will be high (4 to 10 times the

full-load current) and at a low power factor. Consequently, this method of

starting is suitable for relatively small (up to 7.5 kW) machines.

(ii) Stator resistance starting

In this method, external resistances are connected in series

with each phase of stator winding during starting. This causes voltage drop

across the resistances so that voltage available across motor terminals is

reduced and hence the starting current. The starting resistances are gradually

cut out in steps (two or more steps) from the stator circuit as the motor picks

up speed. When the motor attains rated speed, the resistances are completely

cut out and full line voltage is applied to the rotor.

This method suffers from two drawbacks. First, the reduced

voltage applied to the motor during the starting period lowers the starting

torque and hence increases the accelerating time. Secondly, a lot of power is

wasted in the starting resistances.

(iii) Autotransformer starting

This method also aims at connecting the induction motor to a

reduced supply at starting and then connecting it to the full voltage as the

motor picks up sufficient speed. Fig. (8.31) shows the circuit arrangement for

autotransformer starting. The tapping on the autotransformer is so set that

when it is in the circuit, 65% to 80% of line voltage is applied to the motor.

At the instant of starting, the change-over switch is thrown

to “start” position. This puts the autotransformer in the circuit and thus

reduced voltage is applied to the circuit. Consequently, starting current is

limited to safe value. When the motor attains about 80% of normal speed, the

changeover switch is thrown to “run” position. This takes out the

autotransformer from the circuit and puts the motor to full line voltage.

Autotransformer starting has several advantages viz low power loss, low

starting current and less radiated heat. For large machines (over 25 H.P.),

this method of starting is often used. This method can be used for both star

and delta connected motors.

(iv) Star-delta starting

The stator winding of the motor is designed for delta

operation and is connected in star during the starting period. When the machine

is up to speed, the connections are changed to delta. The circuit arrangement

for star-delta starting is shown in Fig. (8.33). The six leads of the stator

windings are connected to the changeover switch as shown. At the instant of

starting, the changeover switch is thrown to “Start” position which connects

the stator windings in star. Therefore, each stator phase gets V 3 volts where

V is the line voltage. This reduces the starting current.

When the motor picks up speed, the changeover switch is

thrown to “Run” position which connects the stator windings in delta. Now each

stator phase gets full line voltage V. The disadvantages of this method are:

(a) With star-connection during starting, stator phase

voltage is 1 3 times the line voltage. Consequently, starting torque is ( )2 1

3 or 1/3 times the value it would have with D-connection. This is rather a

large reduction in starting torque.

(b) The reduction in voltage is fixed.

This method of starting is used for medium-size machines

(upto about 25 H.P.).

(v)

Starting of Slip-Ring Motors

Slip-ring motors are invariably started by rotor resistance starting. In this method, a variable star-connected rheostat is connected in the rotor circuit through slip rings and full voltage is applied to the stator winding as shown in Fig. (8.34).

(i)

At starting, the handle of rheostat is set in the OFF

position so that maximum resistance is placed in each phase of the rotor

circuit. This reduces the starting current and at the same time starting torque

is increased.

(ii)

As the motor picks up

speed, the handle of rheostat is gradually moved in clockwise direction and cuts

out the external resistance in each phase of the rotor circuit. When the motor

attains normal speed, the change-over switch is in the ON position and the

whole external resistance is cut out from the rotor circuit.

Speed Control of Induction Motor

The slip of

an induction motor is very small (<3%) so that it is essentially a constant

speed motor. Therefore, it is suitable for use in essentially constant speed

drive systems. However, many industrial applications require several speeds or

a continuously adjustable range of speeds. Traditionally, dc motors have been

used in such adjustable speed applications. However, dc motors are expensive

and require frequent maintenance of commutators and brushes. On the other hand,

the induction motors (squirrel cage motors) are cheap, rugged, have no

commutators and are suitable for high speed applications. The engineers have

devised several methods to change the speed of induction motors.

The relation

between motor speed (N), synchronous speed (Ns) and slip(s) is given by:

N= (1-s) Ns

N=

(1-s)*(120f/P)

This

equation reveals that the speed of an induction motor can be changed by the

following methods:

1. By changing the number of stator

poles(P)

2. By changing the line frequency(f)

3. By changing the slip (s) for a given

load. The slip can be changed by:

a) By changing the applied voltage

b) By changing resistance in the rotor

circuit

c) By inserting foreign voltage of

appropriate frequency in the rotor circuit

1. By changing the number of stator poles(P)

The synchronous speed of rotating magnetic field is inversely

proportional to the number of magnetic poles in stator winding. Stator winding

can be designed in such a way that they can be connected as 2-pole or 4-pole or

6-pole with the help of special switch and accordingly we can operate the motor

at three different speeds, but smooth change in speed is not possible with this

method.

2. By changing the line frequency(f)

From the formula of the synchronous speed of the induction motor, we know

that by changing the line frequency f, the synchronous speed Ns of the motor

and hence the running speed N can be changed. A major difficulty with this

method is that it involves the use of 3-phase variable frequency power supply.

3. By changing the applied voltage

We know that the torque developed (T) by an induction motor is directly proportional to the square of applied voltage (V) i.e TaV2. Therefore, by changing the applied voltage, the torque and hence speed (or slip) of the motor can be changed. Fig 10.21 shows the arrangement to control the speed of induction motor by changing the applied voltage.

Limitation: The stator voltage control method is

the cheapest and the easiest method of speed control of induction motors.

However, it is rarely used because of the following drawbacks:

a) A large change in voltage is required

for a relatively small change in speed.

b) The large change in voltage results in large change in the flux density. This affects the magnetic conditions and hence performance of the motor.

1. By changing rotor circuit resistance

This method of speed control is suitable only for slip ring motors. The

speed of the motor can be decreased by adding external resistance to the rotor

as shown in fig. Under normal running condition, the relation between torque

(T) and slip (s) of an induction motor is given by:

T a (s/R2)

R2 is the rotor resistance per phase. It is clear from the above equation that for a given torque, s a R2. Therefore slip can be increased by increasing the rotor resistance

Cascade Connection Method

In this method of speed control, two motors having different number of

poles are mounted on a common shaft as shown in figure 8.16. The stator winding

of the motor A is supplied by main supply voltage of frequency ‘f’. The second

motor B is supplied by the voltage induced in the rotor of the first motor A through

slip rings. Therefore the frequency of voltage applied to the stator of the

second motor will be different from the main supply frequency. Now the two

motors will try to run with two different speed corresponding to two different

frequencies. As the both motors are couple to a common shaft, the system will

run at a new speed.

Induction Generator

If an induction motor whose stator

windings are connected to a 3-phase line is driven by a prime-mover at a speed

higher than synchronous speed, it acts as a generator. It converts the

mechanical energy it receives from the prime-mover into electrical energy and

this electrical energy is supplied to the mains. Such a machine is called an

induction generator or asynchronous generator. When speed of the generator

exceeds the synchronous speed, the slip(s) becomes negative.

As soon as the engine speed exceeds

the synchronous speed, the motor becomes a generator, delivering active power P

to the electrical systems to which it is connected. However, to create its

magnetic field, the motor has to absorb reactive power Q. this power can come

only from the lines. Consequently, the reactive power Q flows in the opposite

direction to the active power P as shown in fig.

We have seen that an induction generator will deliver power only if it is supplied with proper reactive power to create its magnetic field. For this reason, an induction generator is generally connected to a 3-phase line. However, reactive power may be supplied by a group of capacitors connected to the terminals of the motor as shown in fig. in that case, the induction generator does not require external source for supply of reactive power.

Voltage

Build up process in Induction Generator

An induction machine with capacitors connected across its terminals, when driven by a prime mover, builds up the voltage in a manner similar to that of a de shunt generator. The voltage build-up process in a dc machine depends upon the residual magnetism in the field poles and the final steady terminal voltage is determined by the resistance of the field circuit. In case of the induction generator, the residual magnetism in the magnetic circuit of the machine is sufficient to generate a small ac voltage in the stator. This small ac voltage causes the capacitor to draw a leading current or a lagging magnetizing current through the magnetizing reactance.

When a proper value of capacitor is

selected, the magnetizing current can be made sufficient to increase the

existing air gap flux. With an increased air gap flux, induced voltage

increases resulting in more magnetizing current to flow. This process of

voltage build-up continues until induce voltage reaches a limit constrained by

the saturation curve of the machine and the reactance of the capacitor. The

steady state value of the emf generated corresponds to the point of

intersection between magnetization curve and volt-amp characteristic of the

capacitor.

|

| Fig: Equivalent circuit for no load excitation circuit |

iµ= Magnetizing current

Xm

= Magnetizing reactance

e = emf

induced in stator

Self-excitation occurs when Xc ≤ (Xm + X)

Curve ‘a’ shown in fig 11 is the magnetization characteristics of the machine and the lines C1, C2, C3 and C4 represents the volt-amp characteristics of different rating capacitors used for excitation.

For any point on the excitation curve, e/iµ

= (Xm+X)

= XC

If the induction generator is operated to supply only isolated local load without connecting the inter-connected power system bus, then such operation is known as isolated mode of operation. It is clear from the T-S characteristic shown in Fig.12 that the induction generator operates at different slip (speed) at different loading condition. At full load it operates at slip 's1', whereas at no-load it operates at slip 's2'. Hence, if the water flow into the turbine is not regulated to match the varying load condition, the frequency of generated voltage varies from full load to no-load.

However, if the water flow into the turbine is not regulated (i.e. constant discharge and head is maintained) and electronic load controller is used, the speed and frequency call be made constant at the varying load conditions. The electronic load controller keeps the total load on the generator constant as shown in Fig.13.

When the consumer's load decreases or increases by some

amount, the electronic control circuit will increase or decrease the power

consumed by ballast load by same amount so that the total power consumption (PL

+ PB) remains constant and equal to power generated by the generator

(PG) resulting in constant speed operation at varying consumer's

load conditions.

Induction generator is more robust and cheaper than

synchronous generator. But an induction generator cannot generate reactive

power demanded by the load. Whereas, synchronous generator can generate

reactive power demanded by the load with the help of dc excitation system

provided in the rotor winding. Induction generator is becoming more popular in

Micro Hydro Power (MHP) plant in rural area, where the consumer's loads are

mostly resistive (lighting and heating).

Induction generator in grid connected mode of operation:

If the induction generator is connected to the bus of large inter-connected grid system as shown in Fig.14, then such operation is known as grid connected mode of operation. In such operation, no Electronic load controller is required. At varying mechanical power input from the turbine, the induction generator injects varying amount of power to the grid and frequency of voltage of induction generator will be automatically constant and equal to grid voltage and frequency. The voltage and frequency of grid always remains constant, because it has frequency governors and voltage controllers in the power stations of the grid. In this mode of operation, even the excitation capacitor is not required. The grid supplies reactive power required for induction generator to maintain air-gap flux.

Synchronizing to grid:

The synchronizing

process of Induction Generator to grid is very simple with compare to that for

Synchronous generator. The IG is driven by turbine keeping the switch (S1) open

and speed is gradually increased by opening the turbine valve. When the speed

reaches little greater than the synchronous speed, then the switch (S1) shall

be closed as shown in Fig.15 , then the IG gets synchronized automatically and runs at constant speed which is little greater than the

synchronous corresponding to the slip.

Unit 2: Single Phase Motors

Single-phase motors are the most familiar of all electric motors because they are extensively used in home appliances, shops, offices etc. It is true that single phase motors are less efficient substitute for 3-phase motors but 3-phase power is normally not available except in large commercial and industrial establishments. Even where 3-phase mains are present, the single-phase supply may be obtained by using one of the three lines and the neutral.

Types of Single-Phase Motors

Single-phase motors are generally built in the fractional-horsepower range and may be classified into the following four basic types:

1. Single-phase induction motors

(i) split-phase type (ii) capacitor type (iii) shaded-pole type

2. A.C. series motor or universal motor

3. Repulsion motors

(i) Repulsion-start induction-run motor

(ii) Repulsion-induction motor

4. Synchronous motors

(i) Reluctance motor (ii) Hysteresis motor

Single-Phase Induction Motors

Construction and Concept of pulsating field produced by single phase winding

A single phase induction motor is very similar to a 3-phase squirrel cage induction motor. It has (i) a squirrel-cage rotor identical to a 3-phase motor and (ii) a single-phase winding on the stator.

Unlike a 3-phase

induction motor, a single-phase induction motor is not self-starting but

requires some starting means. The single-phase stator winding produces a

magnetic field that pulsates in strength in a sinusoidal manner. The field

polarity reverses after each half cycle but the field does not rotate.

Consequently, the

alternating flux cannot produce rotation in a stationary squirrel-cage rotor.

However, if the rotor of a single-phase motor is rotated in one direction by

some mechanical means, it will continue to run in the direction of rotation. As

a matter of fact, the rotor quickly accelerates until it reaches a speed

slightly below the synchronous speed. Once the motor is running at this speed, it

will continue to rotate even though single-phase current is flowing through the

stator winding. This method of starting is generally not convenient for large

motors. Nor can it be employed fur a motor located at some inaccessible spot.

This strange behavior of single-phase induction motor can be explained on the

basis of double-field revolving theory.

Double-Field Revolving Theory

This theory is based on the fact that an alternating sinusoidal flux (ɸ= ɸm cos wt) can be represented by two revolving fluxes, each equal to one-half of the maximum value of alternating flux (i.e., ɸm/2) and each rotating at synchronous speed (Ns = 120 f/P, w= 2*pi*f) in opposite directions. The above statement will now be proved. The instantaneous value of flux due to the stator current of a single-phase induction motor is given by;

ɸ=ɸm coswt

|

| Fig 9.14 |

|

| Fig 9.15 |

|

| Fig 9.17 |

iii. The effect of the shading coil is to cause the field flux to shift across the pole face from the unshaded to the shaded portion. This shifting flux is like a rotating weak field moving in the direction from unshaded portion to the shaded portion of the pole.

|

| Fig: Salient pole rotor |

|

| Fig: Cylindrical type rotor |

|

| Fig 10.4 |

|

| Fig. (10.14) |

|

| Fig.(10.16) |

|

| Fig.(10.17) |

|

| Fig.(10.19) |

|

| Fig.(10.45) |

|

| Fig.(10.46) |

|

| Fig.(10.50) |

|

| Fig.(10.51) |

It should be noted that

the shorting strip, which short circuits the rotor bars, contains holes for

bolting to the next set of damper winding on the next pole. In this way, a

complete squirrel cage winding is formed. Although the bar's' are not of the

capacity to carry the rated synchronous motor load, they are sufficient to

start the motor as induction motor—Star-Delta or auto transformer' methods are

used to reduce the starting current drawn by the motor. It is practically

impossible to start a synchronous motor with its field excited. Even with

un-excited condition, the rapidly rotating magnetic field of the stator will

induce extremely high voltage in many turns of the field winding. Therefore.,

it is better to short circuit dc field winding during the starting period;

whatever voltage and current are induced in it may then aid in producing

induction motor action.

All the above methods shall be used with the synchronous motor without load. In order to start the synchronous motor with load, phase wound damper winding shall be used so that external resistance can be inserted to produce high starting torque. Fig.9.21 shows the schematic diagram of phase wound damper winding for starting synchronous motor.

Such

motor will have rotor with five slip ring. Two for the dc field excitation and

three for ac star connected wound damper winding The motor is started with full

external resistance per phase and dc field circuit open As the motor approaches

synchronous speed, the starting resistance is reduced and, when the field

voltage is applied, the motor pulls into synchronism.

Equivalent diagram

No-load and Loaded operation:

It had already been

explained that a synchronous motor is not self-starting. It had to be speeded

up to synchronous speed by some auxiliary means, the supply to the rotor

winding of the rotor had to be switched on, then the rotor poles will get

magnetically locked up with stator poles. However the engagement between the

stator and rotor poles is not absolutely rigid one. As the load on the motor

increases, the rotor progressively tends to fall back in phase (but net in

speed) by some angle, but the motor still continue to with the synchronous

speed.

At no-load, if there is no power loss in the motor, the stator poles and rotor poles will be along the same axis and phase difference between the applied voltage ‘V’ and the back emf (developed in the armature winding) will be exactly 1800 (See Fig9.22(a) ). But this not possible in practice because some power loss takes place due to iron loss and friction loss. Hence the rotor pole lags by some angle 'a' with the stator pole and the phasor diagram will be as shown in Fig.9.22(b) The current drawn by armature at no-load is given by

Ia = (V-Eb)/Zs = ER/Zs

ER = Net voltage across the armature

Zs = Synchronous impedance per phase

In case of dc motor, the

speed of the armature decreases with increase in load due to which the back emf

decrease and then the armature current will increase to overcome the increased

load. But in case of synchronous motor, the speed does not change with load

When the load on a synchronous motor increases, the rotor poles lags the stator

poles by larger angle ‘a’ and the phase between V and Eb will

increase (note that magnitude of Eb will remain constant) so that

the net voltage ER will increase and the armature current will increase.

Effect of Excitation

The dc current supply to

the rotor field winding is known as excitation in synchronous motor. As the

speed of synchronous motor is constant, the magnitude of back emf remains

constant provided the flux per pole produced by the rotor does not change. If

the magnitude of back emf can be changed by field excitation. If the excitation

is changed at a constant load, the magnitude of armature current and power

factor will change. By changing the excitation, the motor can be operated at

both lagging and leading power factor. This fact can be explained as follows:

The value of excitation for which the magnitude of back emf Eb is equal to applied voltage V is known as 100% excitation. If the excitation is more than 100%, then the motor is said to be over excited and if the excitation is less than 100%, then the motor is said to be under excited.

Consider a synchronous

motor operating with a constant load. Fig 9.23(a) shows the phasor diagram for

the case of 100% excitation i.e. when Eb= V (in magnitude). The armature

current Ia lags behind V by a small angle Ø. ϴ is

the phase angle between Ia and ER, whose magnitude is given by ϴ

= tan-1(Xs /Ra ). Since Xs and Ra are constant, angle ϴ also

remains constant.

If the motor is under

excited, the magnitude of Eb will be less than V. Therefore the resultant of Eb

and V (i.e. ER) will shift upward by some angle, then the direction

Ia will also shift by same angle so that angle ϴ

again remains constant as shown in fig.9.23 (b). Here the magnitude of Ia has

increased and Ia lags V by greater angle so that power factor is decreased, but

the active component Ia cos ϴ remains same so that

output power also remains constant.

Fig.9.23(c) represents

the condition for over excited motor (i.e. when Eb>V). Therefore the resultant

voltage vector ER is pulled in the anti-clockwise and Ia also is

shifted in anti-clockwise direction. It is seen that now motor is drawing a

leaking current. It may also happen for same value of excitation, that Ia may

be in phase with V. i.e. power factor is unity as shown in fig-.9.23(d). At

this instant the current drawn by motor is minimum.

The following two

important points shall be understand clearly from the above discussion."

i) The magnitude of armature current varies with excitation. The current has larger values at both low and high values of excitation. In between. it has minimum value corresponding to a certain excitation for which power factor is unity The variation of Ia with excitation are shown in fig.9.24 which are known as 'V' curves.

ii) For the same input,

armature current varies between a wide range and power factor also vary

accordingly with excitation. When over excited motor runs with leading power

factor and the motor runs with lagging power factor when under excited. The

variations power factor with excitation is also shown in Fig 9.24 and known as

inverted 'V' curve. It would be noted that minimum armature current

corresponding to unity power factor.

Power angle Characteristic of Cylindrical Rotor Machines:

Fig.9.25 (a) shows the circuit diagram and phasor diagram of a synchronous machine in generating mode and Fig.9.25 (a) shows the 'circuit diagram and phasor diagram of a synchronous machine in motoring mode. The machines are assumed to be connected to the infinite bus bar having a voltage of ‘Vt’ and resistance of the stator winding is neglected and only the reactance of the machine has been considered.

From the eqn (9.8) it is clear that the electrical power of the machine P, is proportional to Sind, where 5 is the phase angle between Vt and Eb. This angle 5 is known as power angle. The eqn (9-8) can be represented by a curve as shown in Fig.9.26.

Servo

motors

A servo system is one in which the output is some mechanical variable like position, velocity or accelerators. Such systems are automatic control systems in which output is some mechanical function such as controlling the position of the shaft, controlling angular speed of the shaft etc. As seen earlier, the motors used in such control systems are driven by the signal which is derived based on the error information supplied to the controller. These motors used in such servo systems or servomechanism are called as servomotors. These motors are low power rating motors and can drive the load directly, hence these motors are usually coupled to the load through a gear train for power matching purpose.

|

| Figure 1 Servo mechanism |

The servomotors are basically classified depending upon the nature of the electric supply used for its operation. The electric supply can be a.c. or d.c. in nature hence basic classification is obviously a.c. servomotors and d.c servomotors.

Types

1.

AC

Servomotors

2.

DC

Servomotors

a.

Field

Controlled DC Servomotors

b.

Armature

Controlled DC Servomotors

c.

Permanent

Magnet Armature Controlled DC servomotors

Stepper

motor (stepping motors or step motors)

A

stepper motor is an electromagnetic motor that rotates by a specific number of

degrees in response to an input electrical signal. Typical step sizes are 2,

2.5, 7.5 and 15 degrees for each electrical pulse. It is to be noted that there

is no continuous energy conversion (electrical to mechanical) so that motor

does not rotate continuously as in a conventional electric motor.

Construction

of Permanent magnet stepper motor

It

consists of stator and rotor. Fig shows a two phase, two pole PM stepper motor.

The stator coils are grouped to form 2 phase winding i.e. phase A winding and

phase winding B winding. The phase winding terminals are brought out for dc

excitation.

|

| Figure 2 Construction and operation of PM stepper motor |

Operation of PM stepper motor

For

this stepper motor, the number of rotor poles Nr=2 and number of phases m=2

Step

angle,a=360/(m*Nr)=90 degree/step

I.

When

only phase A winding is excited by a

contant curresnt as shown in fig I, stator tooth 1 becomes south pole. This makes

the north pole of the PM rotor to align (parallel) with the south pole (stator

tooth 1) of the stator. The rotor will remain locked in this position as long

as phrase A winding remains energized. Under this condition step angle a=0.

II.

If

phase A winding is de-energised and phase B winding is energersed as shown in

fig ii, stator tooth 2 becomes south pole. As a result, the north pole of the

PM rotor aligns with the south pole of the stator. Thus the rotor has displaced

90 degree in the anticlockwise direction.

III.

If

phase B is de-energised and phase A is excited with reverse current ( current

in it is opposite to the case I above) , the rotor will further rotate 90

degree in anticlockwise direction as shown in fig iii.

IV.

So

far the rotor has completed one half revolution. However, if we continue the

appropriate switching, the rotor will complete one revolution in 90 degree

steps.

We can change the step angle (a) of

a stepper motor by changing the number of rotor poles Nr and the number of

phases (m).

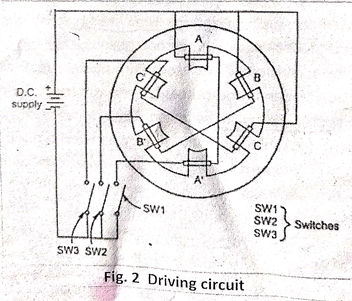

Driving

Circuit of Stepper motor

A

Stepper Motor Driver is a circuit or device that provides the necessary current

and voltage to a Stepper Motor so that it has a smooth operation. A Stepper

Motor is a type of DC Motor that rotates in steps. The main difference between

a simple DC Motor and a Stepper Motor is that through a Stepper Motor, we can

achieve precise positioning with the help of digital control. A Stepper Motor

rotates precisely by synchronizing the pulse signals from a controller, which

are given through a Driver. A Stepper Motor Driver is a circuit that takes the

pulse signals from a controller and converts them in to Stepper Motor Motion.

Two axis AC machine

It

is known that in case of non-salient pole type synchronous machine, the air gap

is uniform. Due to uniform air gap, the field flux as well as armature flux

vary sinusoidally in the air gap. In non-salient rotor machine, air gap length

is constant and reactance is also constant. Due to this the mmfs of armature

and field act upon the same magnetic circuit all the time hence can be added

vectorically. But in salient pole type machines the length of the air gap

varies and the reluctance also varies. Hence the armature flux and field flux

cannot vary sinusoidally in the air gap. The reluctances of the magnetic

circuits on which mmfs act are different in case of salient pole motors.

Hence

the armature and field mmfs cannot be treated in a simple way as they can be in

a non-salient pole machines. In two axis machine, the armature mmf can be

divided into two components.

1.

Components

acting along the pole axis called direct axis.

2.

Component

acting at right angles to the pole axis called quadrature axis.

The

component acting along direct axis can be magnetizing or demagnetizing. The component

acting along quadrature axis is cross magnetizing. These components produce the

effects of different kinds.

Let

Fi be the mmf wave produced by field winding, then it always acts along the

direct axis. This mmf is responsible to produce an excitation emf Ef which lags

Ff by an angle 90 degree.

When

armature carries current, it produces its own mmf wave FAR. This can

be resolved in two components, one acting along d-axis (cross-magnetising). Similarly,

armature current Ia also can be divided into two components, one along direct

axis and along quadrature axis.

Sir, there is an absence in the explanation of the second point of operation of split phase induction motors.

ReplyDelete